Safety:

Temporary personal protective equipment is designed for one purpose only, to protect the worker.

Grounding equipment should be manufactured to and maintained to the highest standards.

Standards:

Very stringent requirements are specified by the ASTM F855 standard. While this is a voluntary

standard, we design all our clamps, cables and ferrules to exceed the values of this standard.

The withstand values from ASTM are:

Grade 15 Cycle

(kA)

30 Cycle

(kA)

Cable Size

(Copper)

Continuous

Current

Rating

A RMS

1 14 10 #2 200

2 21 15 1/0 250

3 27 20 2/0 300

4 34 25 3/0 350

5 43 30 4/0 400

Quality:

Whether it’s the machining of the casting, the assembly of the clamp, or the assembly of the complete

grounding or jumper assembly, we pride ourselves in the quality of the product that is created at Hast-

ings. Every employee that handles the parts is vigilant for any quality issues.

Material:

Clamps are available in either bronze alloy or aluminum alloy metals. Great care is taken in selecting the

best materials for the performance required. The bronze alloys allow for higher strength and higher melt-

ing temperatures. Aluminum alloys allow for lighter weight and less resistance.

Experience:

Hastings works closely with the utility industry in solving grounding problems. Through our close con-

tact with our customers, we stay in touch with their needs and this guides our efforts for future product

designs. Hastings also participates in the development of industry standards.

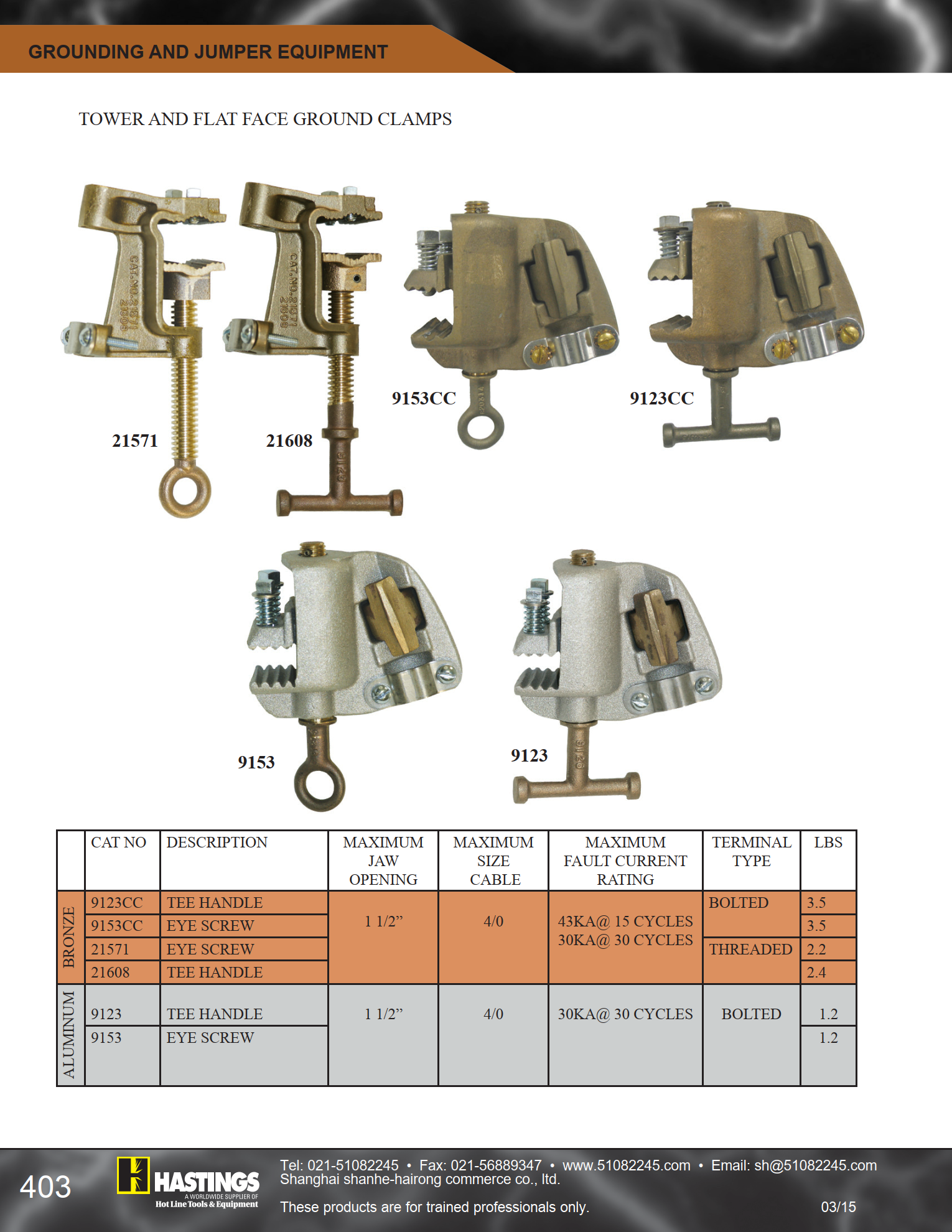

TOWER AND FLAT FACE GROUND CLAMPS

CAT NO DESCRIPTION MAXIMUM

JAW

OPENING

MAXIMUM

SIZE

CABLE

MAXIMUM

FAULT CURRENT

RATING

TERMINAL

TYPE

LBS

BRONZE

9123CC TEE HANDLE

1 1/2” 4/0 43KA@ 15 CYCLES

30KA@ 30 CYCLES

BOLTED 3.5

9153CC EYE SCREW 3.5

21571 EYE SCREW THREADED 2.2

21608 TEE HANDLE 2.4

ALUMINUM

9123 TEE HANDLE 1 1/2” 4/0 30KA@ 30 CYCLES BOLTED 1.2

9153 EYE SCREW 1.2